An air cushion machine is a packaging device used to inflate air cushion film rolls, helping businesses create protective packaging on demand. When selecting a machine, users often compare factors such as brand, materials, functions, and price. Even within the same brand, different models are designed for different packaging needs.

To make the selection process more straightforward, here are three essential features to evaluate: inflation speed, film width compatibility, and supported film types.

Different air cushion machine models offer different maximum inflation speeds. For example, a high-performance model may reach speeds of up to 30 meters per minute, allowing users to quickly produce large volumes of air cushions.

Inflation speed matters because packaging scenarios vary—small batches, medium-volume warehouses, or high-frequency e-commerce fulfillment centers all require different output levels. A fast machine helps maintain packaging consistency while significantly improving productivity.

A versatile air cushion machine supports multiple film widths, making it adaptable to various packaging applications. By switching to different film roll widths, users can easily handle small parcels, medium boxes, or large shipments.

Film width compatibility ensures that the machine fits a wider range of products, allowing businesses to select the appropriate film size based on their packaging needs without purchasing multiple machines.

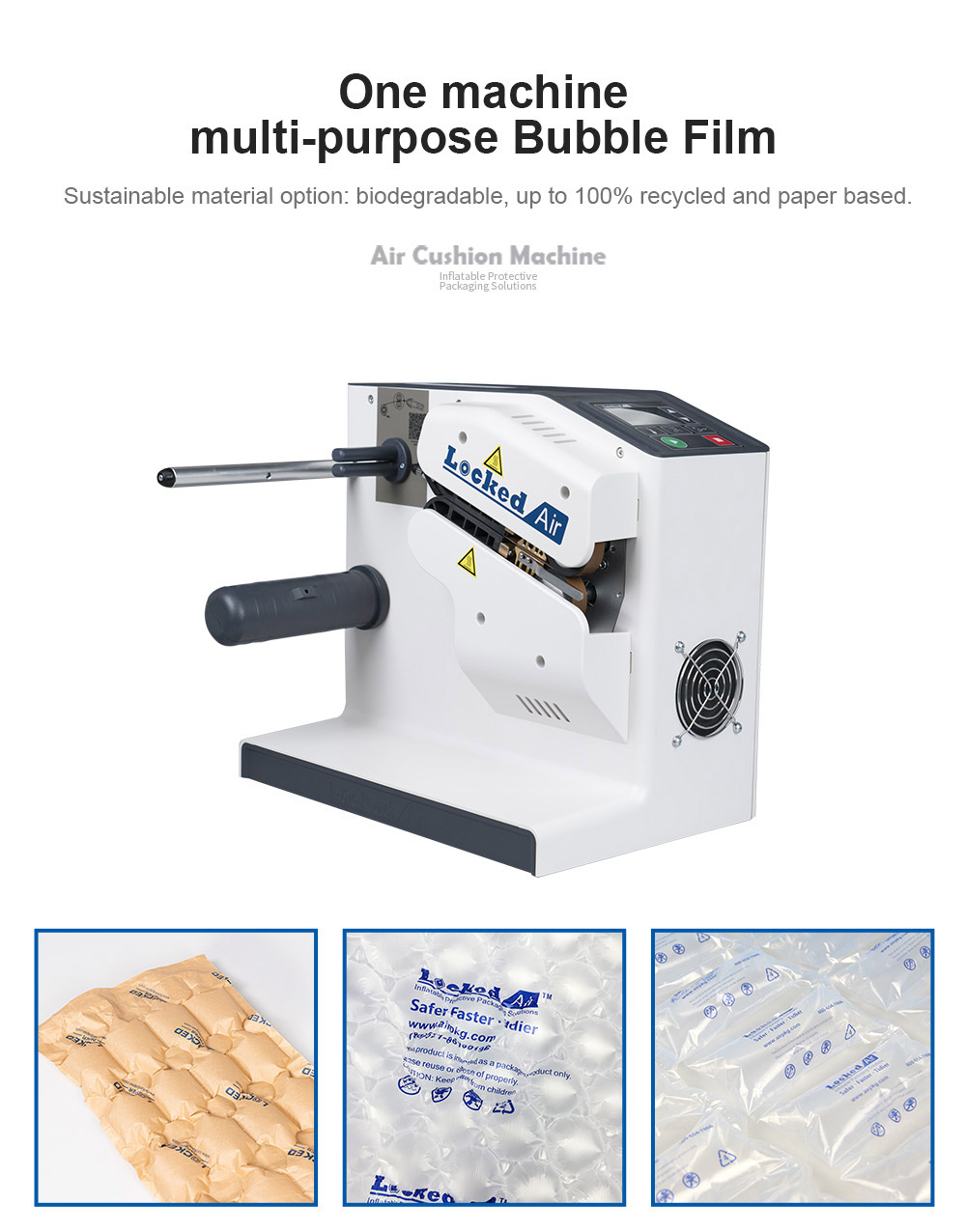

Some air cushion machines are designed to be multifunctional, supporting a wide range of films such as bubble film, air pillows, and air column film. Other machines may focus on a single film type for specialized applications.

Before choosing a machine, users should consider which air cushion formats match their typical packaging requirements. Selecting the right film compatibility helps achieve better protection and cost efficiency.

Evaluating inflation speed, film width compatibility, and supported film types provides a simple and intuitive way to compare air cushion machines. These features directly affect packaging flexibility, production efficiency, and operational cost. By focusing on these core factors, businesses can identify the machine that best fits their actual workflow.

BJT Pack’s LockedAir systems offer high efficiency, strong sealing performance, and compatibility with a wide range of air cushion films—helping warehouses achieve smooth, reliable, and cost-effective packaging operations.

For solutions tailored to your products, feel free to contact our team.