Almost all enterprises are talking about sustainable development, but which way is more suitable for China's national conditions? There are always bold pioneers in this industry, and Lockedair is also one of them.

Headquartered in Hangzhou, Zhejiang Province, Lockedair has become an industry leader with four factories and whose business scope covers more than 40 counties across the globe. And all these achievements depend on continuous innovation and mergers in the past 10 years. As changing times, Lockedair also keeps innovating. With enthusiasm and persistence and the combination of innovation and science, Lockedair aims to improve the products used in people's daily life at present and in the future through packaging.

Then here comes the question - when sight words such as "sustainable", "green and environmental protection" and "plastic reduction " appear frequently in relevant reports on all walks of life in recent years: - what measures will Lockedair, as the leader in protective packaging, take to provide users with packaging solutions that adapt to the sustainable development of the times? There are so many directions, recyclable, reusable, degradable, and reducible... Which road will Lockedair give priority to? Plastic, a packaging material closely related to our lives. So what does Lockedair think about the future trend of plastics?

Under the background that the enterprise sustainable development strategy is increasingly high on the agenda, PACKCHINA visited Lockedair's headquarters in Hangzhou, China's artificial intelligence town, and interviewed Mr. Fang, director of Lockedair's overseas business department.

During the interview, we mentioned many issues of great concern to end-users, such as:

-"Can plastic packaging still be used?"

-"Under the dual pressure of stricter plastic restrictions by the domestic government and the Global Sustainable Vision 2025, how can enterprises survive?"

-"What are the shortcomings in the establishment of a domestic plastic recycling system?"

At this time, we stand at the moment and predict the future of the plastic industry - the process may be biased, but more importantly, we can see Lockedair's unchanging and consistent persistence and attitude through this way. This is also one of the important reasons why we look forward to having a dialogue with Mr. Fang.

The following is the main content of the interview, which has already been deleted and adjusted.

PACKCHINA:

Let's start with a question that must be raised when it comes to sustainable development. Now, many consumers feel horrible when they hear "plastic". How do you view the role of plastic packaging in the overall packaging industry and consumer market?

SHAWN:

In today's society, the "demonization" of plastic is still very severe. But in fact, plastic packaging is a packaging form that could not be completely replaced. There is a huge demand for it on the end-user side. According to professional research, plastic cushioning packaging has less energy consumption and carbon emissions than protective packaging. Compared with foam, paper, and other materials, it has obvious advantages for environmental balance.

The plastic pollution of the marine environment that we often talk about is indeed caused by improper disposal of plastic packaging after its abandonment, not the problem of plastic packaging itself. It is inappropriate to simply consider plastic packaging as a form of packaging harmful to the environment.

PACKCHINA:

You have just mentioned that improper disposal of plastic packaging is the source of pollution. Is there a better way to deal with disposable plastic packaging in the industry? Which method does Lockedair mainly take?

SHAWN:

At present, the more popular sustainable development methods for packaging materials in the industry include, but are not limited to development of degradable plastic materials (compostable) and bio-based plastic materials, recycling and reuse of plastics, reduction of packaging materials, research and development of alternative packaging materials for plastics, etc. At present, China is still in the exploration and trial stage of the establishment of a recyclable economy, so either way has its unique advantages and value.

However, from the perspective of Lockedair, we believe that recycling is our main focus. At present, biodegradable plastics have some applications, such as products like garbage bags which are suitable for short-term and specific use. Due to the problems of overall output and cost, as well as the limitations of its performance, large-scale promotion is not realistic. Although paper-based and biodegradable plastics are new choices, they could not achieve environmental protection without considering the final recycling.

Take the implementation system of waste classification and recycling in Shanghai as an example. In the past, plastic packaging bags were used as dry waste. Their final treatment was usually incineration or landfill, which did not achieve the effect that new materials should play. After the implementation of the waste classification system, effective data showed that the number of plastic landfills in Shanghai was reduced by 50%. So starting from the recycling end is also an indispensable perspective to fundamentally solve the problem of plastic pollution.

PACKCHINA:

Since Lockedair supports the establishment of a scientific plastic recycling system, have you taken or will you take action in the future to promote the establishment and improvement of the recycling system and clear up consumers' misunderstanding of plastic packaging?

SHAWN:

At the beginning of 2018, Lockedair draw up and launched the "reusing plan of recycled materials". Through research, development, and innovation, Lockedair has made up to 100% buffer packaging of recycled materials in various ways and has already achieved the mass production of 50% recycled products.

PACKCHINA:

All of your examples just focus on Lockedair's practice in recyclable plastic packaging. As far as we know, Lockedair has also made many attempts and practices in reduction and recycling. Can you briefly share the company's practical achievements in these aspects from the perspective of research and development?

SHAWN:

The reduction has always been a very important way for enterprises to save packaging costs. Lockedair has a powerful team composed of 65 pure research personnel in Greater China, focusing on Lockedair's core technical functions such as product development, improvement, and safety. Together with our customers, under the premise of ensuring product performance, we continue to innovate and jointly develop more economical flexible plastic packaging that meets customer needs.

In terms of reuse, China's laws and regulations have restricted the use of recycled materials in the packaging of raw materials of food and drug. Although there are cases that PCR and PIR, namely the packaging products made of recycled materials after consumption and industrial recycled materials, have been reused in the daily chemical industry. On the whole, the direct use of recycled materials in the protective packaging industry is not common due to differences in physical properties and appearance.

The reuse I mentioned above belongs to physical recycling. According to the development abroad, chemical recycling may solve the shortcomings of physical recycling. Now relevant technology in the PET industry is in its infancy, while the chemical recycling of PE polyolefin materials has just started. Mass industrialization is still a work in progress. This is one of the new technologies that Lockedair has been focusing on.

PACKCHINA:

So in your opinion, what are the difficulties in building a perfect plastic recycling system in China?

SHAWN:

Well, there are three major difficulties.

First of all, the strength of a single enterprise is too weak. The amount of waste packaging produced by the numerous domestic waste plastic recycling suppliers is only hundreds of thousands of tons every year. Compared with the total amount of plastic used in China, the percentage of recycling is still very low. Lockedair, as the leading enterprise in domestic protective packaging and the pioneer of soft plastic packaging recycling, is also actively seeking government support. We often participate in various activities of industry associations, NGOs, and other partners, including the formulation of various laws, regulations, and standards related to the circular economy, waste plastics, and packaging. In this way, we can strengthen the education of users and expand our influence. Of course, the government's strength and support should not be ignored. The establishment of China's waste recycling system is a good example, enabling the recycled soft plastic packaging to be degraded for use, which is also an attempt to extend the life cycle of soft plastic packaging. From development end to recycling end, from packaging manufactures to consumers, from soft plastic packaging recycling, sorting to reuse, and so on, different parts cooperate, make joint efforts, influence each other, and help each other forward.

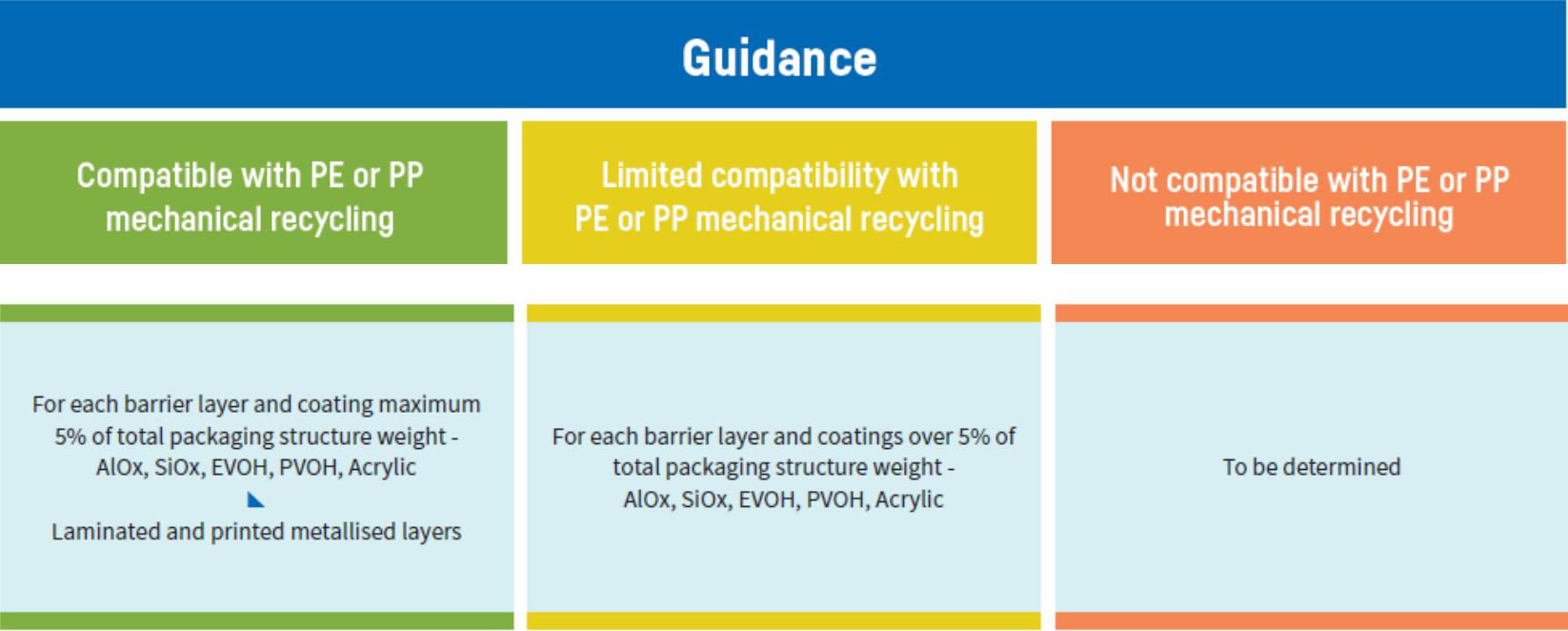

Second, consumers don't know which form of plastic packaging can enter the recycling system and what kind of packaging is not up to cycle standards. There are no explicit regulations or standards for recyclable soft plastic packaging across the globe. After in-depth communication with customers, we have set standards that meet the cycling definition of Lockedair. We believe that the following three categories of products are in line with the general recyclable plastic packaging standards.

1. Structure that contains aluminum: aluminum-based packaging with an aluminum content of more than 80%;

2. Structure that contains paper fiber: paper-based packaging with paper fiber accounting for more than 80%;

3. Pure polyolefin structure: mainly are PE and PP. And its density is less than 1, without adding PET, PVC, PVDC, paper fiber, etc. The content of other polymer materials does not exceed 5% (such as nylon, EVOH, etc.).

At present, our products mainly focus on the research, development, and production of products two and three. We also introduced high barrier flexible protective packaging materials made from a single material in June 2021 to replace the popular aluminum-plastic and film-covered composite materials in the market. We also hope to cooperate with relevant institutions and organizations to contribute to the global recycling industry of plastic packaging by establishing recyclable plastic packaging standards.

Finally, we still have to start from the end packaging users. Some of our customers often hope to achieve the ambitious goal of sustainable development with the least change - after using the new packaging that is in line with the environmental protection structure, its production efficiency, and shelf life will remain unchanged, and the control cost will not rise. This is indeed the ideal state we pursue, but the reality is that at this stage no sustainable solutions for plastics will have their cake and eat it too. Therefore, while developing packaging products, Lockedair also considers the possibility of its commercialization, thus achieving real sustainability. Everything is based on the commercial operation. Choosing among various factors and a product that achieves a relative balance in an application is the goal that we expect to achieve.

On the other hand, at present, it is still the leading enterprises such as Procter & Gamble and Alibaba that pay constant attention to sustainable development and recycling and put forward innovative environmental protection schemes and structures for us, because these leading enterprises also have their own sustainable development goals and roadmap. Ordinary small and medium-sized customers are less involved, and most enterprises are still mainly concerned with chronic problems like cost reduction and efficiency enhancement. The reason is that the demand for environmental protection is still in the starting stage in China rather than being the rigid need of enterprises. But we believe that with our 2025 sustainable development deployment plan, more in-depth market education and guidance, and the maturity of various national laws and regulations, more and more enterprises will embark on the road of cooperation in sustainable development.

Lockedair divides the solution into three steps, hoping to give some enlightenment to enterprises that have started or are on the road to take the step of sustainable development:

1. The already formed recycling material product scheme is easy to operate and mature, which can first start replacing work;

2. What Lockedair is doing more at present, and what our customers are also paying more attention to, is the potentially achievable and recyclable solutions;

3. The recyclable scheme to be developed requires us to summarize the needs with customers and then jointly develop it, which is also relatively difficult.

In a word, only when the whole industrial chain of the packaging industry acts together can the construction and operation of the packaging circulation system be achieved. Recently, the implementation of regulations on producer responsibility is soliciting opinions, which may be a good direction.

PACKCHINA:

In consideration of the closed-loop construction of plastic collection, recycling, and reuse in China, is there any unique innovation in Lockedair's business at the development end right now?

SHAWN:

The core research and development business segment of our strong R&D team is carried out around the needs of our customers. The main work and R&D direction of our R&D department are as follows:

1. Improve performance and save cost: cooperate with customers to develop high-strength innovative products and realize low-cost material replacement.

2. Achieve extreme thinning. Through process innovation, thinner cushioning packaging products become possible. The introduction of a 10um air pillow and 20um High separation membrane reduces the introduction of new materials with the same cushioning effect by 30%.

3. Single component recyclable materials at present. The most commonly used materials in the industry are nylon film and aluminum-plastic film, which are composed of multiple components and can not be effectively recycled. We have introduced pure PE film composed of a single component that meets the EU class A recyclable standard and the recoverable high resistance diaphragm containing EVOH that meets the EU class B + recycling standard;

4. Recycled cushioning products. We are the first cushioning packaging company in China that has completed the GRS (Global Recycled Standard) full supply chain certification. We can achieve mass production of 50% recycled material cushioning bubble films, and 100% recycled films are also in single-customer testing. And we are far ahead of the peer enterprises in the progress of particle product recycling;

PACKCHINA:

Thank you very much for explaining in detail, and Lockedair's efforts and contributions to plastic product recycling. I believe that under the influence of Lockedair, we could also see the common progress of this industry in the direction of environmental protection and recycling.